Due to its extreme hardness, wear resistance and low coefficient of friction, diamond can be a challenge to polish. Unlike equipment used for typical optical materials, diamond polishing equipment must operate with an order of magnitude higher speeds, force and temperature. This makes achieving superior finishes, dimensional accuracy and economic removal rates highly challenging.

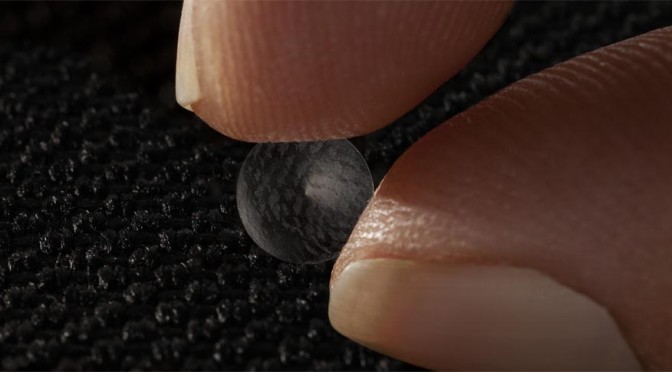

Knowledge of the anisotropic qualities of diamond material removal can help with single crystal diamond. Our highly trained craftsmen create slabs of single crystal diamond as thin as 20um and even thinner plates can be supplied with the addition of dry etching.

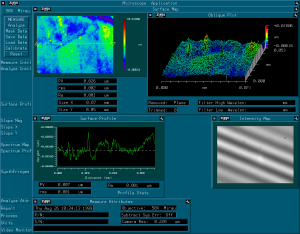

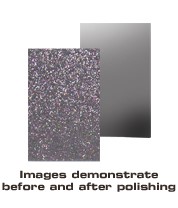

The random crystal orientation of CVD materials, however, creates special problems. In addition, the roughness on the growth surface of a polycrystalline CVD diamond wafer is typically 10% of the film thickness before polishing, 50 um on a 500 um thick film for example. Our specialized equipment and processes will polish polycrystalline diamond to a very smooth, mirror surface resulting in an average roughness (Ra) of less than 10 nm.

Applied Diamond and DDK have been grinding and polishing diamonds for over 30 years. We have proven expertise and the knowledge to tackle any needs you may have, in either single or polycrystalline diamonds. We provide the diamond material you need for your application using material of our manufacture, from our network of sources, or from material that you provide.