Super Polishing with Applied Diamond

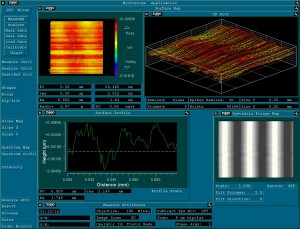

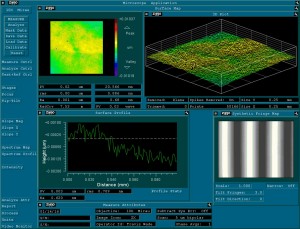

Applied Diamond has perfected the process of polishing diamond to finishes between 0.1 and .3 nm Ra. Using our process, we have put these finishes on diamond slabs with surface areas as large as 5×5 mm.

Why Super Polish?

For Optics:

Super Polished surfaces reduce scattering of light as it passes through the window or lens. For short wavelength applications this can be critical for getting the least amount of scattering. This polish, along with the unique properties of diamond allows for better optics in extreme heat and other demanding conditions.

For Electronics:

Super Polished diamonds are also useful in heavy particle detectors, as their ultra-smooth surfaces will trap less charge and create more sensitive detectors. Using this technique, Applied Diamond adds more functionality to our detectors or to your own custom design.

Super Polished surfaces have applications in other electronics as well. In conjunction with diamond’s thermal properties, a Super Polish can increase the efficiency of diamond in Schottky barrier diodes, sensors, and as a semiconductor medium. As diamond becomes more widely researched, super fine surfaces will become more important to maximize the benefits it provides.

For Epitaxy:

Super Polished surfaces have much reduced surface and sub-surface damage allowing for faster and more uniform deposition of materials. Achieve better results with your deposition run by using Super Polished seed material or interlayers.

Contact us with any questions and we’ll be happy to help you decide if a Super Polish is right for your application.