Applied Diamond’s lasers have been successfully sawing diamond for many years. Use our laser capability in conjunction with our other processes to produce finished parts from your diamond raw material. You’ll find our engineers knowledgeable regarding what is possible and how we can work together most efficiently and economically.

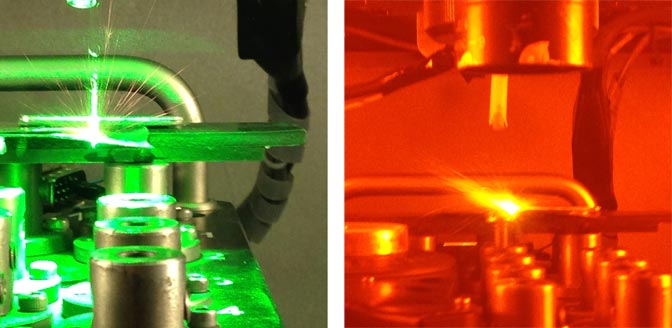

Historically, a Q-switched Nd:YAG laser is used for sawing diamond, whether at its fundamental wavelength of 1064nm or at a multiple of that frequency. The beam delivery optics and the part being cut are moved relative to one another in order to cut parts of specific geometry. The resolution of the moving stages, specifications of the delivery optics, and performance of the laser determine the amount of material removed (kerf loss), quality of the cut and minimum tolerances that can be held.

Our laser spot size is 40 um in diameter and the computer-controlled stages have micron resolution allowing us to hold dimensional tolerances to +/- 10 um. Custom programming permits us to saw samples up to 10 mm thick, although kerf loss increases with thickness from 10’s to 100’s of um. Bread-slicing before polishing is commonly used to get multiple, thinner slabs from valuable raw material.

Computer-controlled motion has advanced to the point where conversion of your drawings into these movements is done automatically. We often say “If you can draw it, we can cut it.” Small and large jobs can be accomplished quickly and economically with this system. We work hard to keep our services quick and inexpensive, too.